The japanese 5s system

5S is a Japanese method, developed by Toyota to create order and method at the workplace.

The 5 S's can be interpreted as:

- Sort the tools and materials that are used at the workplace. Separate what is necessary from what is not.

- Set in order that, which is necessary and easily accessible. Give it a suitable place and remove everything else.

- Shine regularly, some cleaning each day, major cleaning each week.

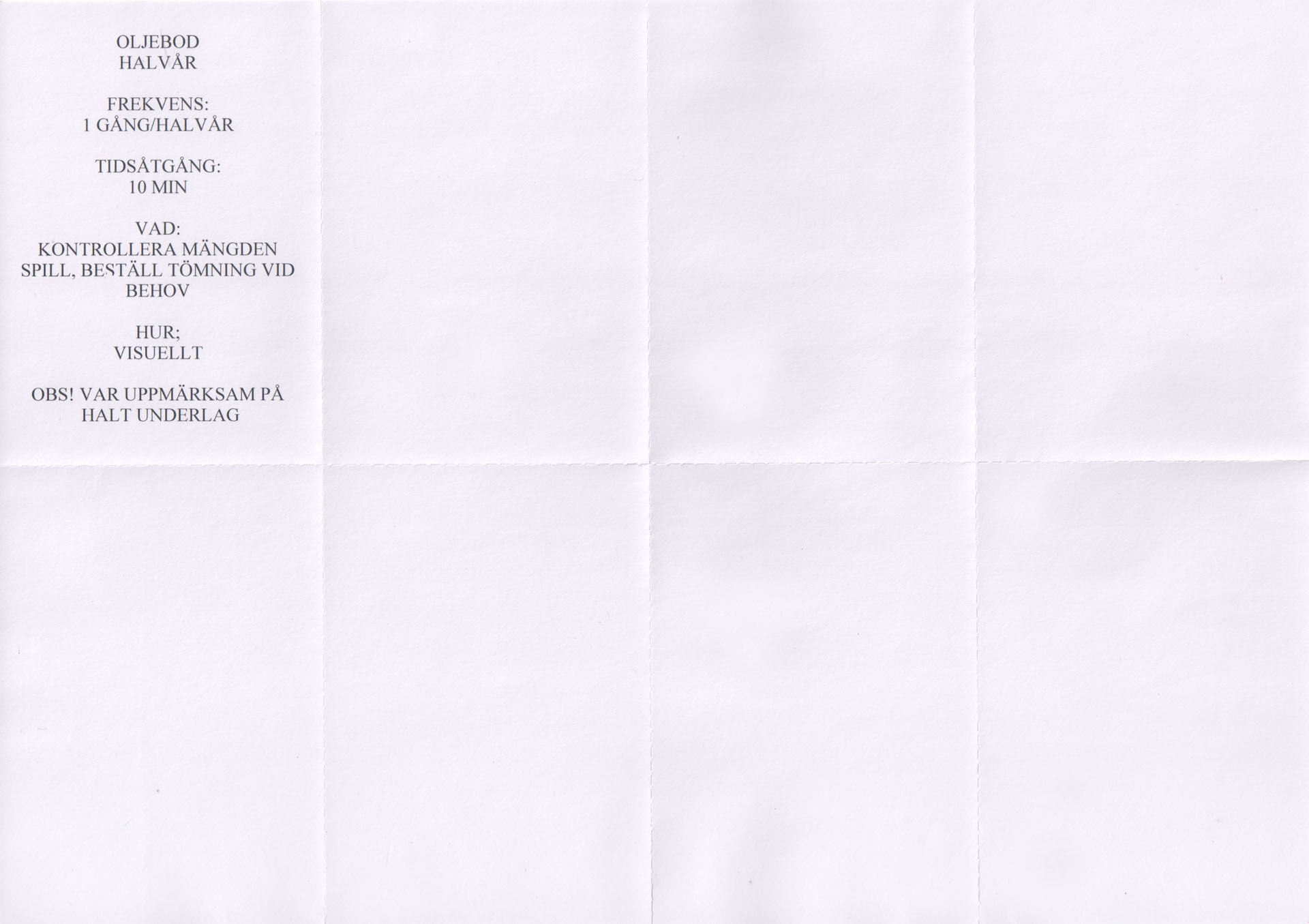

- Standardize the daily routines. Use to do lists for daily upkeep of the machinery and premises.

- Sustain the order. Improve the to-do lists continuously.

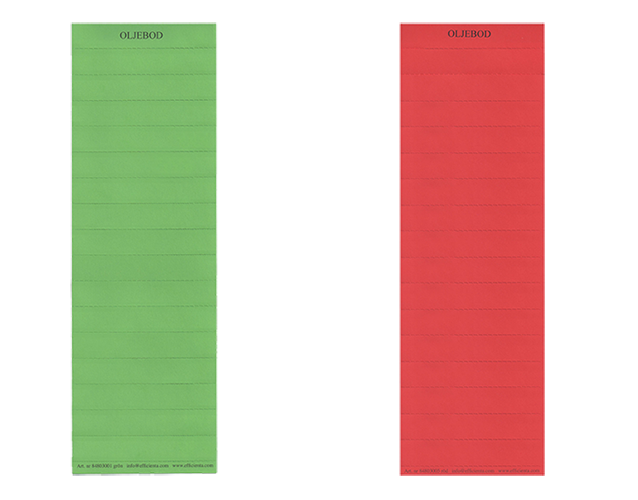

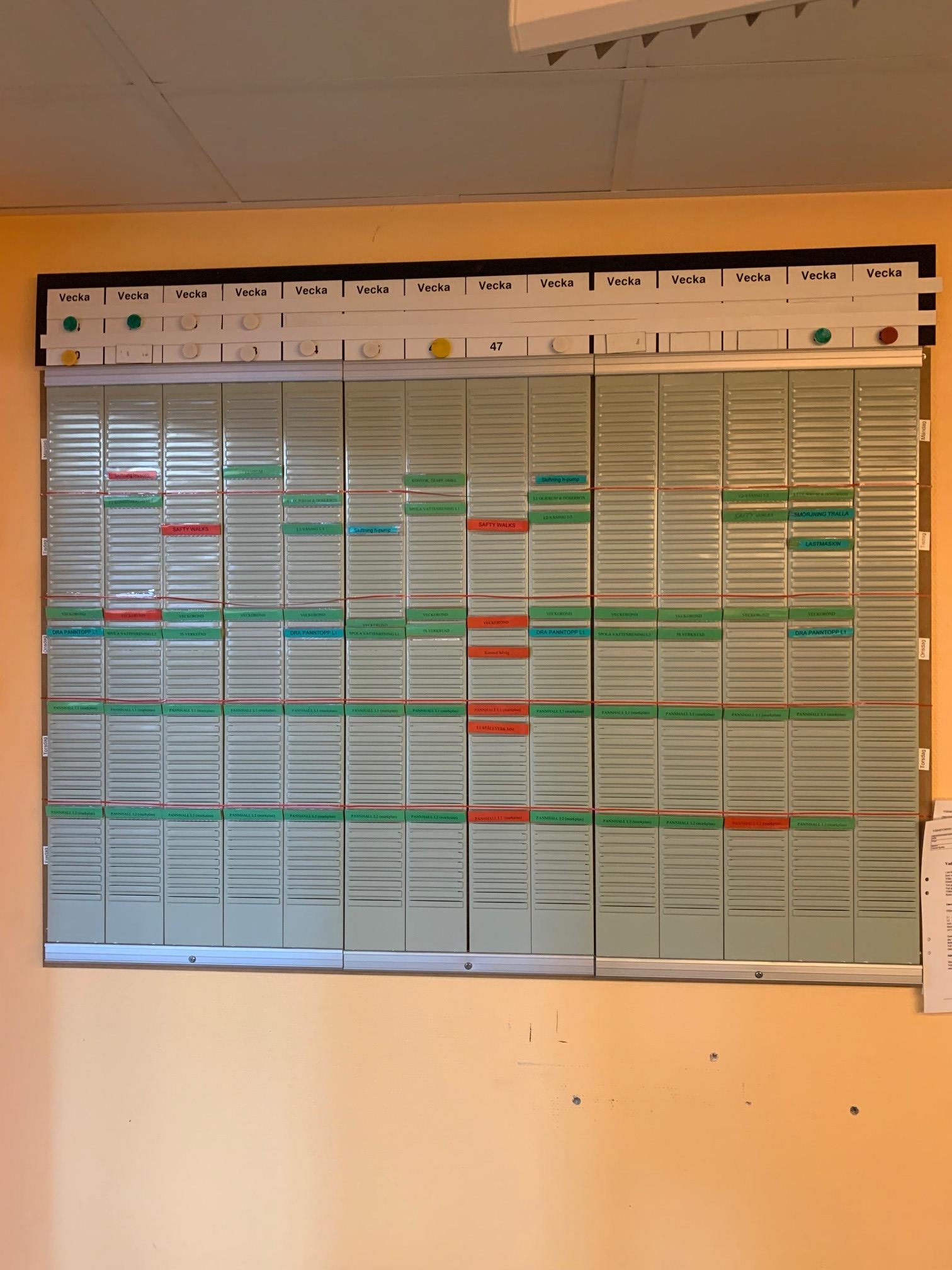

The T-plastic pocket has a green heading/work done/and a red heading/work not done/.

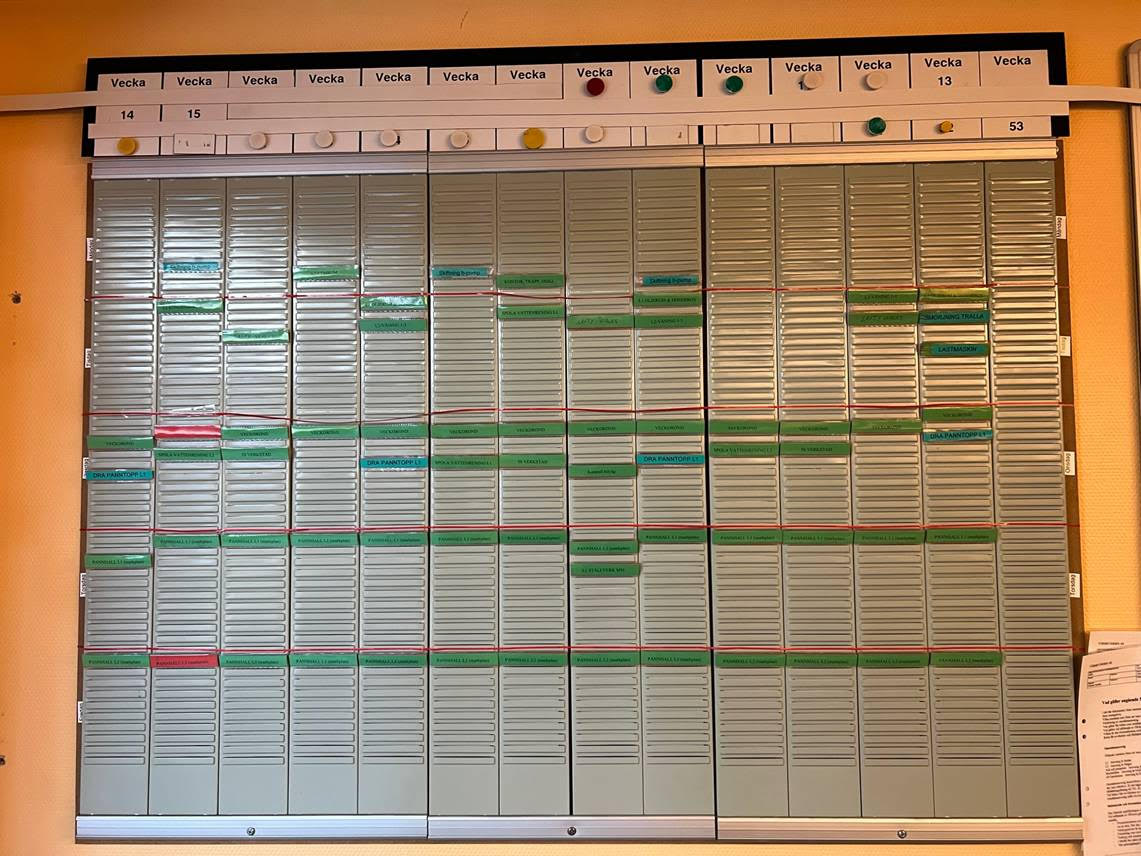

Example of work organisation: You can set the cards week-wise for one or two years ahead.

Products for 5S

T-card planning board. Can be customised as per your needs. 32 and 54 slots.

Item No. 8480 3077 Transparent T-plastic pocket.

Item No. 8480 3076 Printed cards with work tasks.

Item No. 8480 3001 Title inset, green.

Art. nr. 8480 3005 Title inset, red.

The printed cards and title insets are printed using the Efficienta printing program.

Älmhult

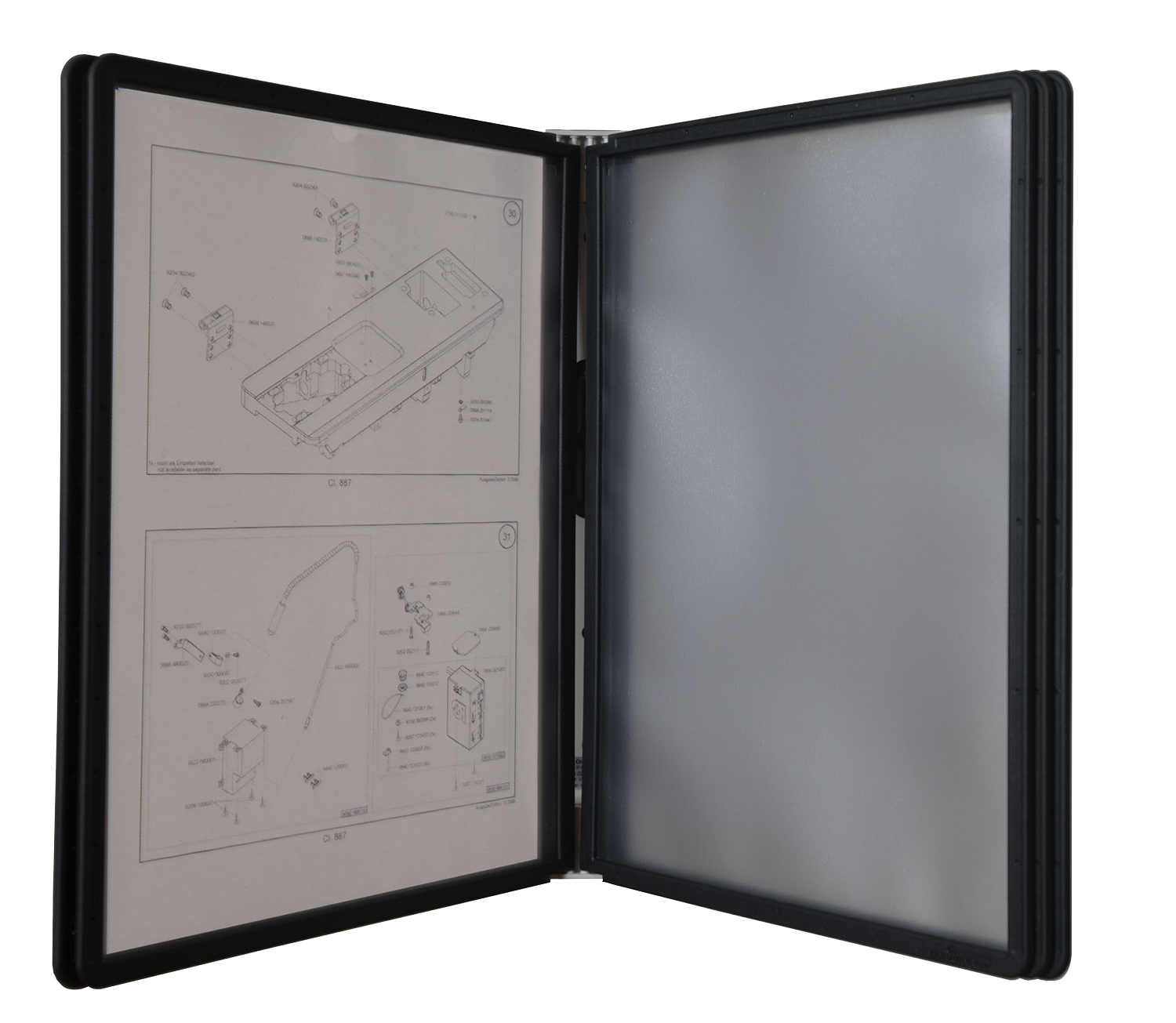

Item No. 8480 3075 Display for ”Order and method”.

5 frames/A4 format. Can be mounted on the wall with magnets or screws.

Flipboardtavla

At a glance, the entire situation becomes clear. It’s easy to quickly make the necessary adjustments. At the same time, you can see if other projects are affected and promptly make the required changes. The overview remains visible and is always up to date for those who need the information for their work.